The Glassblowing Service provides highly specialized maintenance and support services for scientific apparatus. Services include the design, construction and maintenance of sophisticated scientific glass apparatus and glass high vacuum systems.

All items must be clean before dropping off for services.

Examples of the Glassblowing specialized services offered include:

Glass services: In-house Services:

- Pyrex and Quartz Tubing - Cutting to length and grinding edges

- Glass Plates - Cut to size and/or shaped via plate grinders

- Ceramic tubes and plates - Cut to size and/or shaped via plate grinders

- Annealing - Pyrex and Quartz annealing service available, limited size available

- Polariscope to image internal stress

Quartz:

- Ampules in standard wall or heavy wall up to 18mm OD

- (NOTE: Common sizes are 6mm OD, 12mm OD and 18mm OD)

- Sample processing - evacuate, backfill and seal samples in quartz ampule

Pyrex:

- Pyrex cutting and grinding only in house.

- Several third-party sources available to support Pyrex request – please contact us.

Equipment:

- High speed abrasive cutoff saw

- High speed abrasive table saw

- Plate glass grinders

- Hydrogen/oxygen handheld torch and small bench burner

User Training: (provided by David Wright)

- Glass Cutting and grinding

- Glassblowing quartz ampules

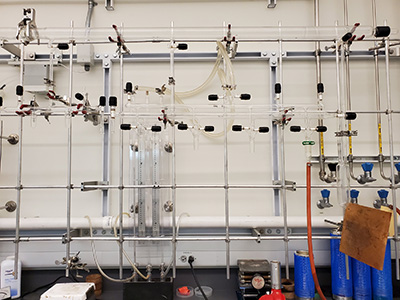

- Quartz ampule sealing on high vacuum manifold #2 (in hood in B14)

If a user has their own manifold and torch, I can train them on their equipment.