AEP Core was contracted by the Defense Threat Reduction Agency’s (DTRA) explosive ordinance disposal group to develop a flexible scintillator phosphor film for application to a flexible substrate digital x-ray detector. A digital x-ray detector is functionally similar to a large digital camera: a light source (x-rays) irradiates a sample to be imaged. The x-rays are attenuated as they pass through the sample and are detected by a digital x-ray detector where the incident x-rays are absorbed by a scintillator phosphor film and converted to visible light. The light is captured by an array of photodiodes connected in series with a thin film transistor fabricated on a large area display glass substrate (similar to a modern television). The light is converted to an electrical signal in the photodiode which is extracted when the transistor is turned on to produce a digital image (see example, Figure 1).

The primary benefit of switching from conventional rigid glass to flexible substrates in digital radiography is a cost savings associated with elimination of the ruggedization that must be incorporated to limit detector breakage. The ruggedization cost depends on the portability of the system. Systems used in the field for threat assessment and on-site medical diagnostics require the most ruggedization. A fully flexible x-ray imager minimizes ruggedization cost and may additionally open digital radiography to new uses such as accident victim triage by first responders and portable and conformable infrastructure monitoring.

The AEP Core previously developed flexible TFT technology as a first step toward a fully flexible digital x-ray detector. The next milestone is to incorporate the scintillator on to the flexible substrate. A modern medical grade x-ray scintillator is a fragile ceramic material with limited flexibility. The sintered scintillator material is sandwiched between a transparent polyester protect film and a white polyester backing to provide structural stability and a reflective surface. AEP Core senior engineer Nick Munizza has perfected a flexible scintillator in binder process originally developed by AEP Core’s Dr. Michael Marrs and Xan Henderson (patent pending).

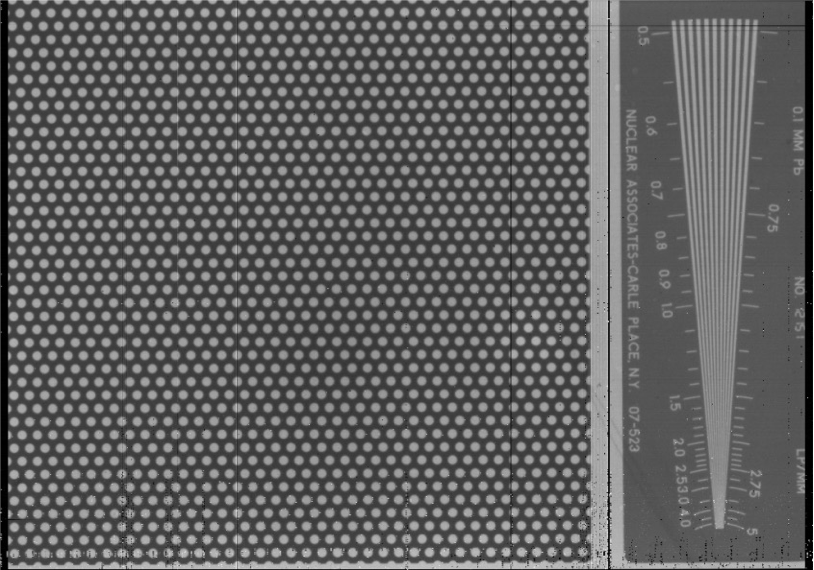

The phosphor in binder solution utilizes the same phosphor found in commercial scintillator screens and can be manufactured for less than half their cost. The AEP Core flexible scintillator also has the advantage of enabling intimate contact with the underlying photodiode. A commercial scintillator is taped or adhered to the photodiode with a small gap. The intimate contact between flexible scintillator and photodiode reduces the chance of image blurring which occurs when a photon from the scintillator is absorbed by a neighboring photodiode as opposed to the photodiode closest to the photo emission. The AEP Core flexible scintillator demonstrates improved resolution over the off-the-shelf scintillator currently used by DTRA, but with reduced intensity. A visual comparison showing the modulation transfer function (MTF) expressed as line pairs per millimeter (lp/mm) is shown in Figure 2.

There is a tradeoff between resolution and intensity with respect to the thickness of the scintillator phosphor film. In theory, the resolution could be sacrificed to provide increased image brightness by simply increasing the thickness of the scintillator film. The advantage to increased brightness is that a lower x-ray dosage is required to produce an image. However, increased resolution is also advantageous depending on the application. AEP Core can tailor the process as needed to applications that require higher resolution or higher brightness.

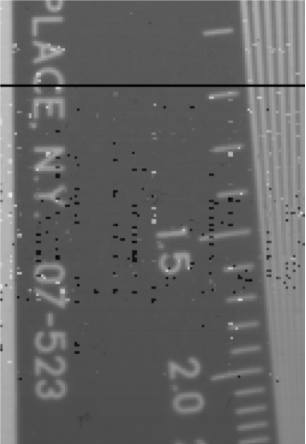

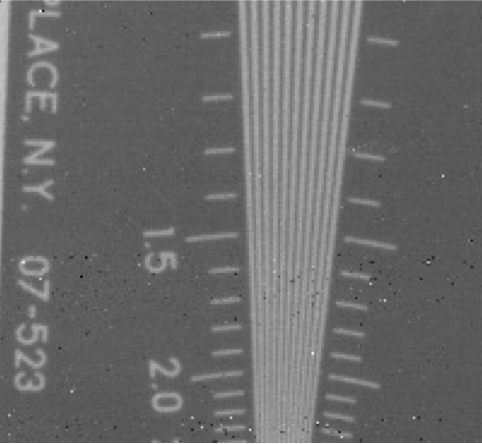

If changing the film thickness becomes impractical, another parameter affecting the resolution and light output of the scintillator is the particle size of the phosphor, with a smaller particle size yielding higher resolution and lower light output. AEP Core produced scintillator screens with a “small” particle size and a “large” particle size (“large” particle size is 3x “small” particle size). Imaging tests with the “small” and “large” particles demonstrate the expected result with the smaller particle size film generating a higher resolution/lower brightness image having light output 20% less than the large particle film. A comparison of the output images is shown below in Figure 3.

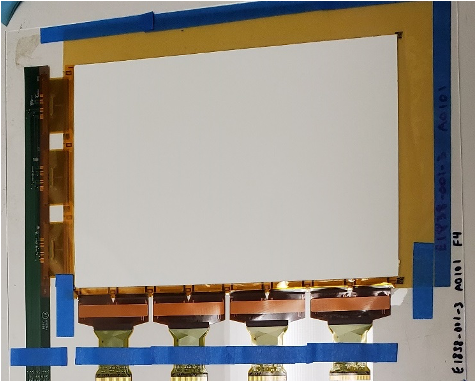

One final advantage of applying the flexible scintillator directly to the flexible array is that the added film thickness stabilizes the backplane which is no more than 25 µm thick prior to the scintillator coat. The array is much less susceptible to creasing and is significantly easier to handle during driver attach assembly operations. The drivers themselves are also affixed to flexible packaging (see Figure 4), leaving the readout electronics as the last obstacle precluding a completely flexible detector.

The AEP Core seeks opportunities to continue bringing flexible electronics to the forefront with ongoing work supporting DTRA and other government agencies. For information on the AEP Core’s flexible thin film transistor process, please contact Michael Marrs (mmarrs@asu.edu).