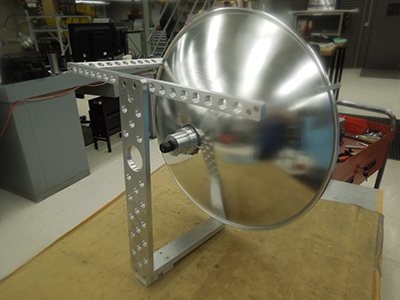

ASU’s full-service Machine Shop provides project design and development services over a wide range mechanical design, prototyping and fabrication services. Specialties include consulting along with the production and support of quality prototypes and instrumentation to fulfill specialized research projects.

Our highly specialized staff can assist in manufacturing your custom project and specialize in a wide variety of machining equipment and processes. Our shop utilizes equipment from several manufacturers such as Atlas Copco, Betenbender, Bridgeport, Brown and Sharp, Clausing, Di-Arco, DoAll, Edwards, Fanuc, Grizzly, Haas, Hardinge, Miller, Mitutoyo, National, Ocean Technologies, Proto Trak, Schaublin and Sharp.

All items must be clean before dropping off for repair services.

Several examples of equipment and processes are below:

Equipment

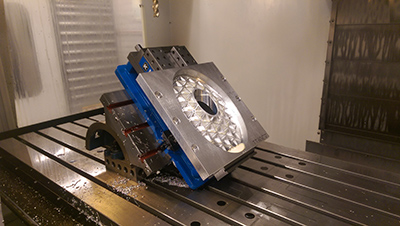

- 2 ½ - 5 axis CNC mills

- CNC lathes

- CMM Inspection

- EDM drill

- Manual mills and lathes

- Sheet metal fabrication

- Wire EDM machining

Processes

- CAD - computer aided design using SolidWorks and other platforms such as Fusion 360 and Inventor.

- CAM – computer aided manufacturing using HSMWorks, FeatureCam and SolidWorks cam programming platforms.

- CMM - Inspection.

- Proof of concept and Rapid prototyping.

- Ultra-high vacuum chamber design, manufacturing and helium leak check detection to 10-12 Torr. (External source for welding).