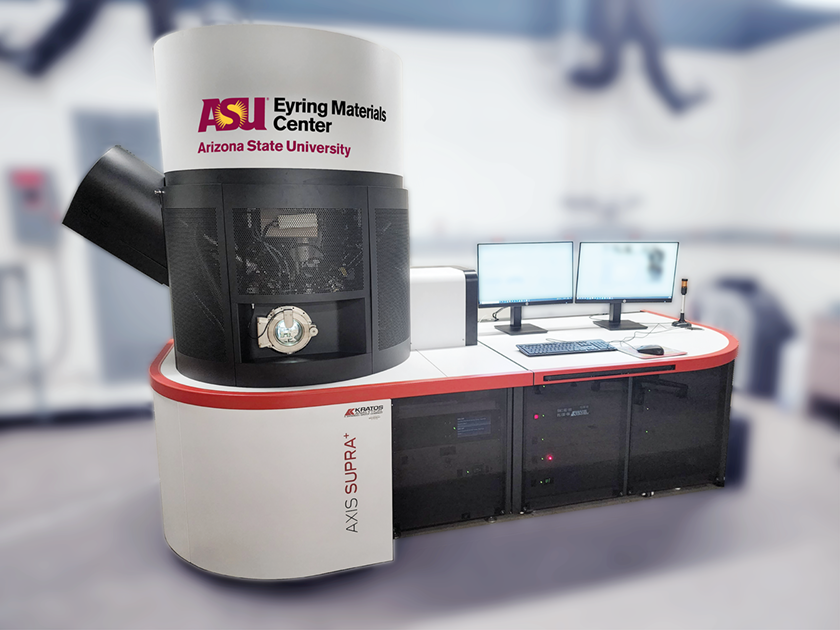

XPS provides elemental composition and chemical bonding information on the sample’s first few atomic layers. XPS is also referred to as Electron Spectroscopy for Chemical Analysis. The technique relies on the emission of secondary electrons from the surface after the near-surface atoms have been excited with X-rays. XPS provides the energy resolution needed to detect elemental peak position and energy shifts due to chemical bond formation.

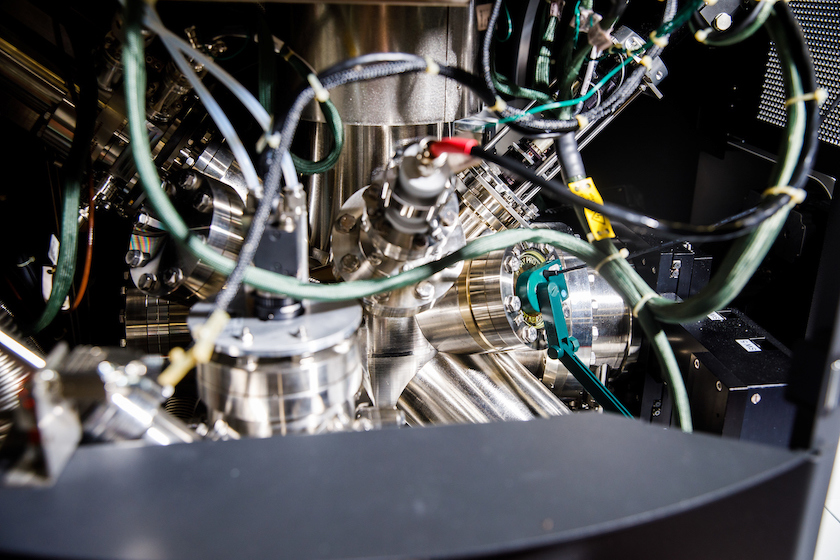

Information is typically obtained for the region within uppermost 10nm surface of materials. Angle-resolved XPS can allow analysis of regions even closer to the sample surface. XPS depth profiling or angle-resolved XPS can be performed to determine elemental composition and chemical bonding information for layers below the surface. Relative atomic concentration percentages can be determined with a sensitivity of 0.1 to 1 atomic % for Li and heavier elements. The analysis is carried out in an ultrahigh vacuum system (~10-9 Torr/10-7 Pa or better).

The complementary options of the Ultraviolet Photoelectron Spectroscopy (UPS), ion scattering spectroscopy (ISS) and Reflection Electron Energy Loss Spectroscopy (REELS) make several new measurements possible, such as valence band spectra and electronic work function, scattering of ions with kinetic energy loss depends on the relative masses of the atoms within a surface, discrete energy losses of the reflected electrons due to excited atomic states and material bandgaps, which are key to understanding electronic band structure, bonding information and much more. With all the sources and the great detection capabilities, the instrument also comes fitted with an argon ion cluster sputter source which will provide a dramatic improvement in the ability to analyze polymers and organic materials.

Features

- Large area XPS analysis with high sensitivity and faster acquisition times.

- Parallel XPS imaging from 10 mm2 to 200μm2 with 1μm ultimate spatial resolution.

- Pre-defined small spot analysis with the smallest diameter 15 μm.

- XPS Depth-profiling in small spot mode and Angle-Resolved analysis.

- Dual monochromatic Al/Ag source with a high-energy resolution (Al K-alpha 1486.6eV & Ag L-alpha 2984.2eV, line width 0.48eV on Ag 3d5/2 and 0.408eV on Si 2p3/2).

- A Minibeam 6 Arn+ cluster ion gun for relative depth profiling and sputtering cleaning.

- Multi-Technique Capability: ultraviolet photoelectron spectroscopy (UPS), ion scattering spectroscopy (ISS), and reflection electron energy loss spectroscopy (REELS).

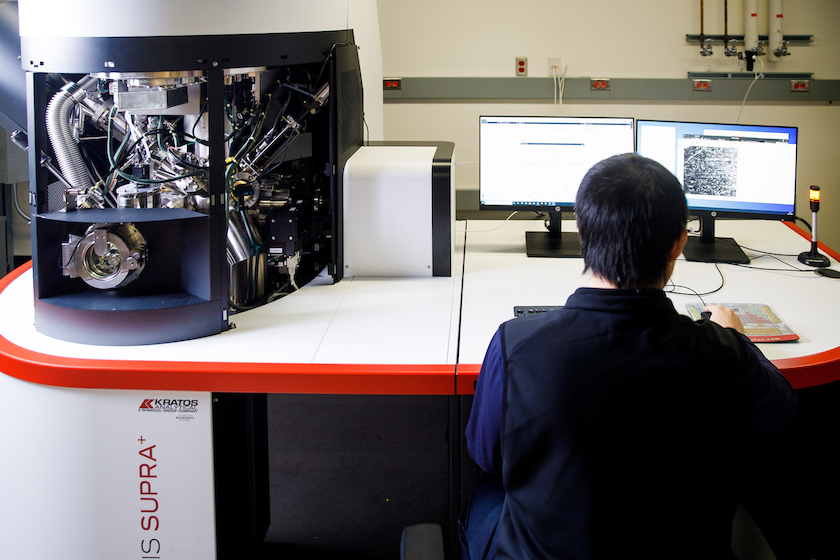

Sample handling

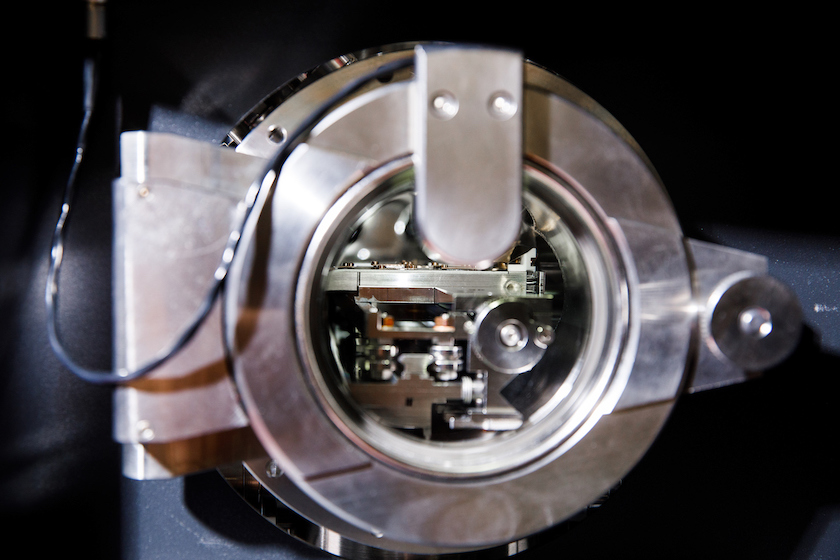

- Versatile sample holders available (Dual height, Stub combined and Z-rotation sample holder).

- Two interchangeable top plates for samples up to 7.5 mm thick and maximum thickness of 14.5 mm.

- Five axis auto-stage system for precision manipulation of the sample holders around axis X, Y, Z and θ, Φ rotations.

- In-situ Sample cooling/heating (-100°C to 800°C).

- An integral charge neutralizer for the analysis of non-conductive materials.

Sample requirements

- Solids with low vapor pressure(s) (Liquids cannot be investigated).

- Samples must be clean according to ultra-high vacuum sample handling procedures.

- Samples must be delivered in clean containers, handled with clean tools, and gloves must be worn during handling.

- Non-standard samples, such as powders, samples with unusual dimensions may be suitable, as determined in consultation with Xin Guo.

Contact

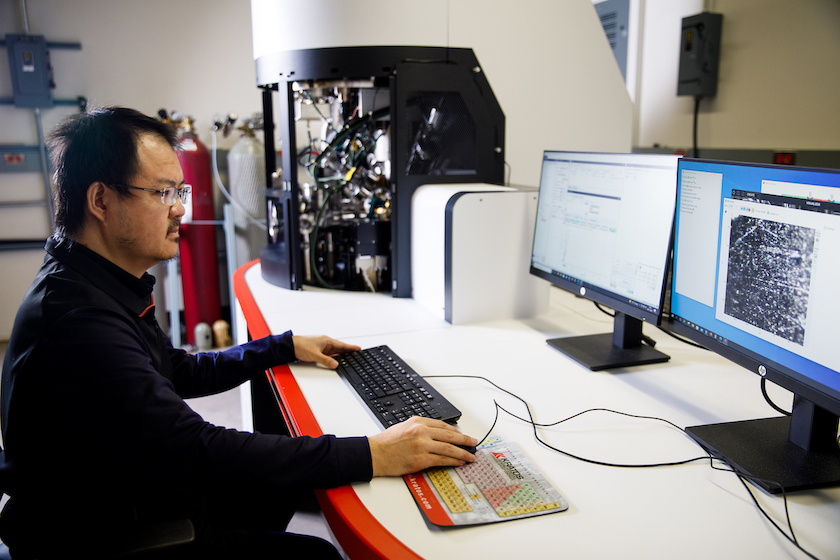

Xin Guo

Research Lab Manager

Phone: 602-543-5986

Email: xguo95@asu.edu

- Surface composition

| Cost for ASU Internal | Cost for ASU Internal with Staff Assistance | Cost for Other Academic/Non-Profit | Cost for Other Academic/Non-Profit with Staff Assistance |

|---|---|---|---|

|

$60.06/h

|

$103.11/h

|

$83.06/h

|

$179.66/h

|