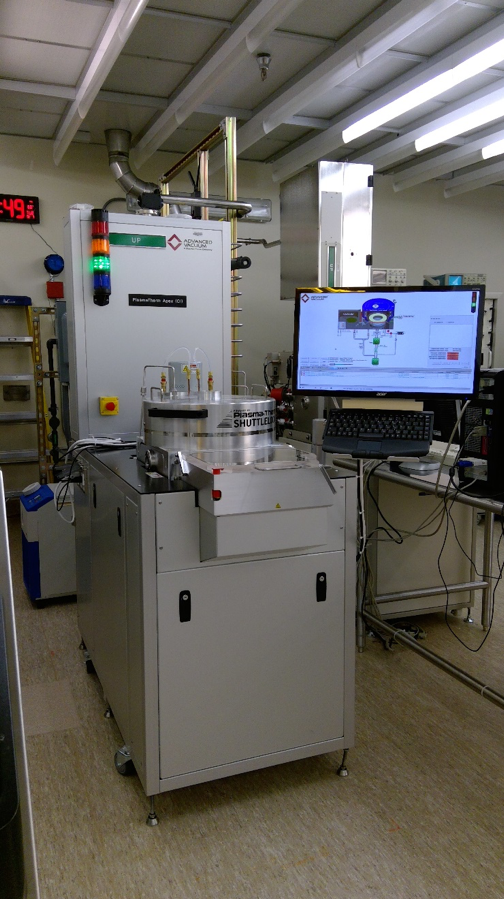

The PlasmaTherm Apex ICP is a highly advanced etch system designed for compound semiconductors and dielectrics. With its load locked, inductively coupled plasma, this system utilizes boron trichloride (BCl3), chlorine (Cl2), oxygen (O2), argon (Ar) and nitrogen (N2) as process gases for highly precise and efficient etching. The tool is capable of accommodating 150 mm wafers with one SEMI flat and irregularly shaped samples on a 150 mm carrier. With an ICP power range of 10-900 watts, a bias power range of 0-900 watts, and a pressure range of 1-900 mTorr, the system ensures high-quality etching for various applications.

______________

The PlasmaTherm Apex ICP is a load locked, inductively coupled plasma etch system. Process gases are boron trichloride (BCl3), chlorine (Cl2), oxygen (O2), argon (Ar) and nitrogen (N2). The system is for the etching of compound semiconductors and dielectrics. Masks allowed in this system are photoresist and dielectrics.

This tool requires pre-requisite training on other techniques: PlasmaLab M80 Plus – Fluorine OR PlasmaLab M80 Plus – Chlorine OR PlasmaTherm 790 RIE – Fluorine.

Specs:

Wafer Size: 150 mm wafers with one SEMI flat. Wafers smaller than 150 mm and irregularly shaped samples must be placed on a 150 mm carrier.

Platen Size: 150 mm.

ICP Power Range: 10 – 900 Watts

Bias Power Range: 0 – 900 Watts

MFC Flow Range: 0 – 100 sccm for all gases.

Pressure Range: 1 – 900 mTorr

Backside Cooling: Helium. Clamped.

- Dry etch, Inductively coupled plasma etching

- FilePlasma Therm Apex SOP Rev NC_0.pdf169.81 KB

| Service | ASU Internal Rate | External Organization Rate | Notes |

|---|---|---|---|

| Equipment use | $52.50 / Hour | Contact NanoFab | Upto 450 watt hours |