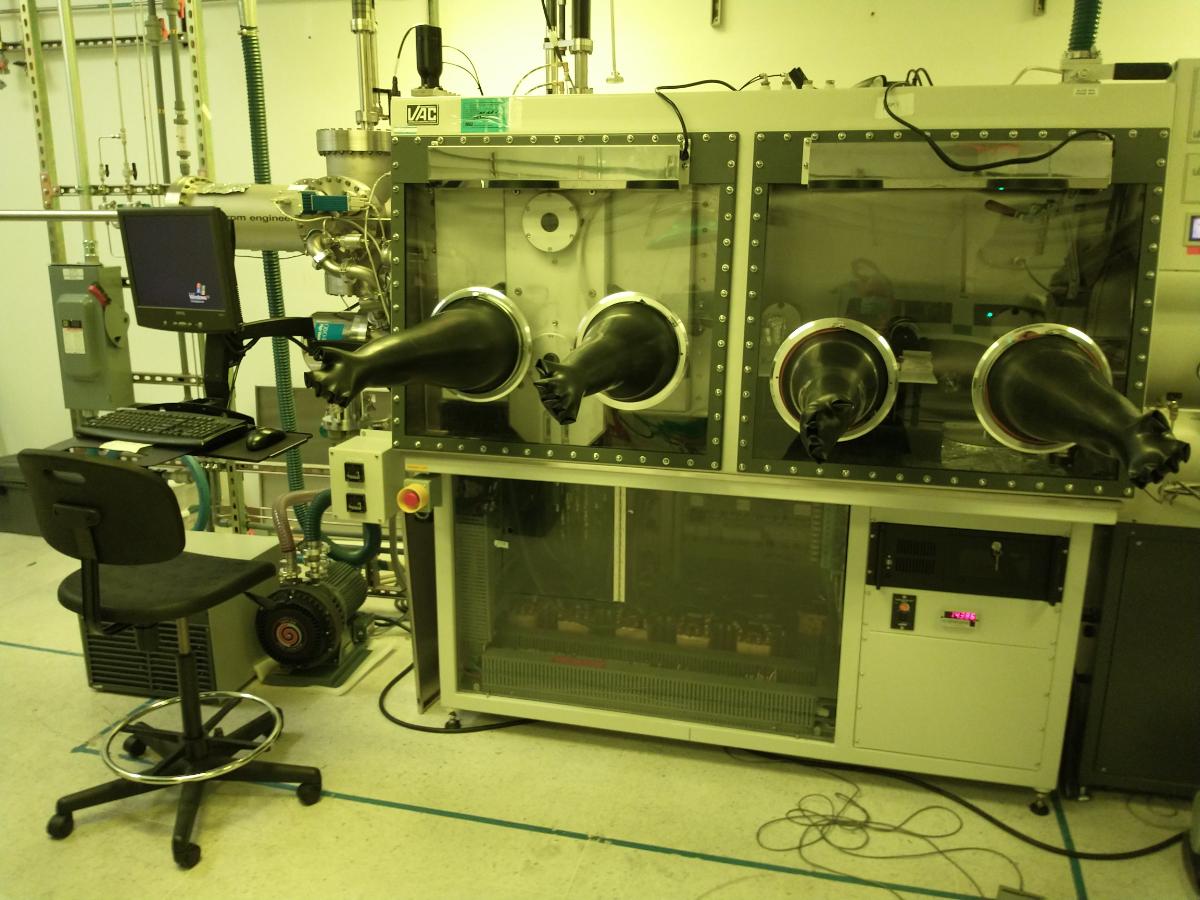

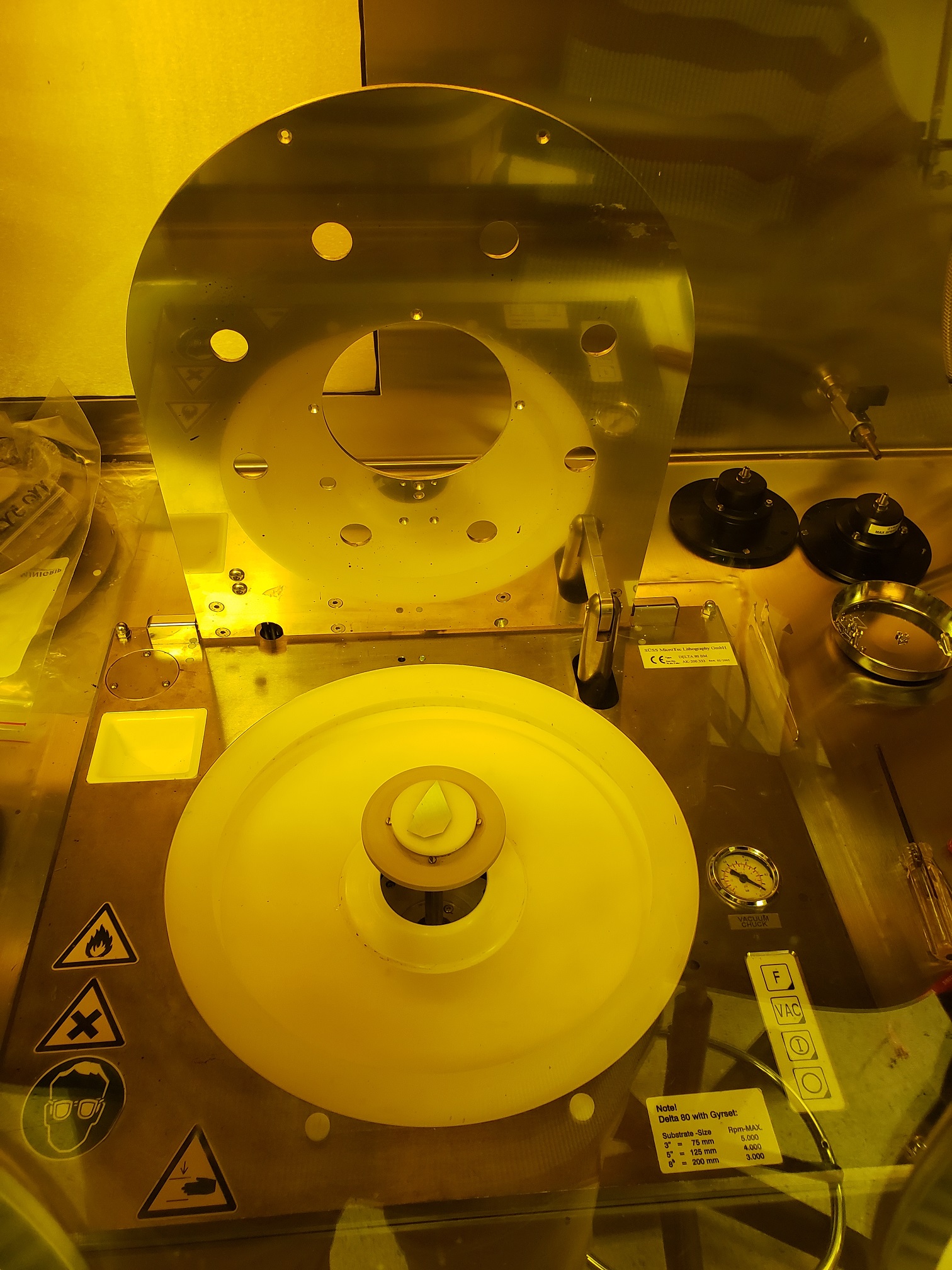

The Angstrom Engineering Glovebox evaporation deposition system with spin coater attachment operates in a nitrogen atmosphere to prevent oxidation or contamination of materials. The evaporation chamber is a vacuum system where material is heated to evaporation or sublimation and the resulting vapor is deposited on substrates directly facing the melt. Additionally, the spin coater attachment allows for the processing of air-sensitive or hazardous materials, such as perovskite precursors. By applying a solution to the solar cell or a fraction of a cell while spinning at a high rate of speed, the spin coater yields a uniform and planar film, although it can be material-inefficient.

__________________

Angstrom #1 is a thermal evaporator for metals and organic materials. The main deposition chamber is connected to a nitrogen-filled glovebox train, which is connected to a spin coater and an L-I-V diode tester. The system was originally designed for researching organic light emitting diode materials, but it is capable of providing deposition coatings for a variety of organic and inorganic electronic devices as well.

The main deposition chamber is fitted with 11 thermal evaporation pockets, of which six can be filled with organic materials and five with metals. There are four quartz crystal monitors with allows for up to four co-depositions to occur simultaneously. Evaporation material can be loaded in ceramic or tungsten boats or draped over the heating element (filament evaporation). The evaporation melt temperature is controlled via applied heating element current, thus a true melt temperature readout is not possible. Be advised that materials with a melting temperature above 1100 °C may not evaporate at all. Low melting point metals such as silver (Ag), magnesium (Mg), and gold (Au) have been successfully evaporated in the Angstrom.

The system can accommodate blanket depositions or patterning with shadow masks. The shadow masks are mechanically aligned, limiting pattern resolution to the millimeter scale. A transfer arm allows for the loading of multiple masks into the chamber which can be exchanged without breaking the system vacuum.

Usage fees for the Angstrom deposition chamber and the attached glovebox spinner module are tallied separately in iLab. If your process requires both the spin coater and the evaporation chamber, you must reserve both in iLab.

- Thermal evaporation

- Filament evaporation

- Nitrogen glovebox spin coating

- File

- FileSQS242_Manual_V3_25.pdf760.01 KB

| Service | ASU rate | Nonprofit/other academic rate | Private/ Industry | Notes |

|---|---|---|---|---|

| Equipment Use – Angstrom Evaporation Chamber | $54/hr | $70/hr | Please contact AEPCore@asu.edu | |

| Equipment Use – Glovebox Spin Coater Module | $54/hr | $70/hr | Please contact AEPCore@asu.edu |