Description

Wet chemical processes

Wafer cleaning is commonly the first step and may be used repeatedly throughout a process fabrication sequence. This may involve the use of acid and basic solutions, followed by a water rinse.

Cleans are designed to remove organic or metallic surface contamination as well as particulates. Furnace pre-cleans consist of a Piranha clean followed by silicon clean 1(SC1) and then silicon clean 2(SC2). Short etch steps are often done prior to metallization to ensure good contacts to semiconductors. Micro Electro-Mechanical Systems (MEMS) processes can utilize a long buffered oxide etches (BOE) for the release step.

Wet chemical etching is available with the following chemicals:

- Buffered oxide etch [BOE = ammonium flouride (NH4F) + hydrogen flouride (HF)] and HF solutions (such as 10 parts H2O + 1 part 49%HF).

- Ammonium hydroxide (NH4OH) + deionized water (diH20).

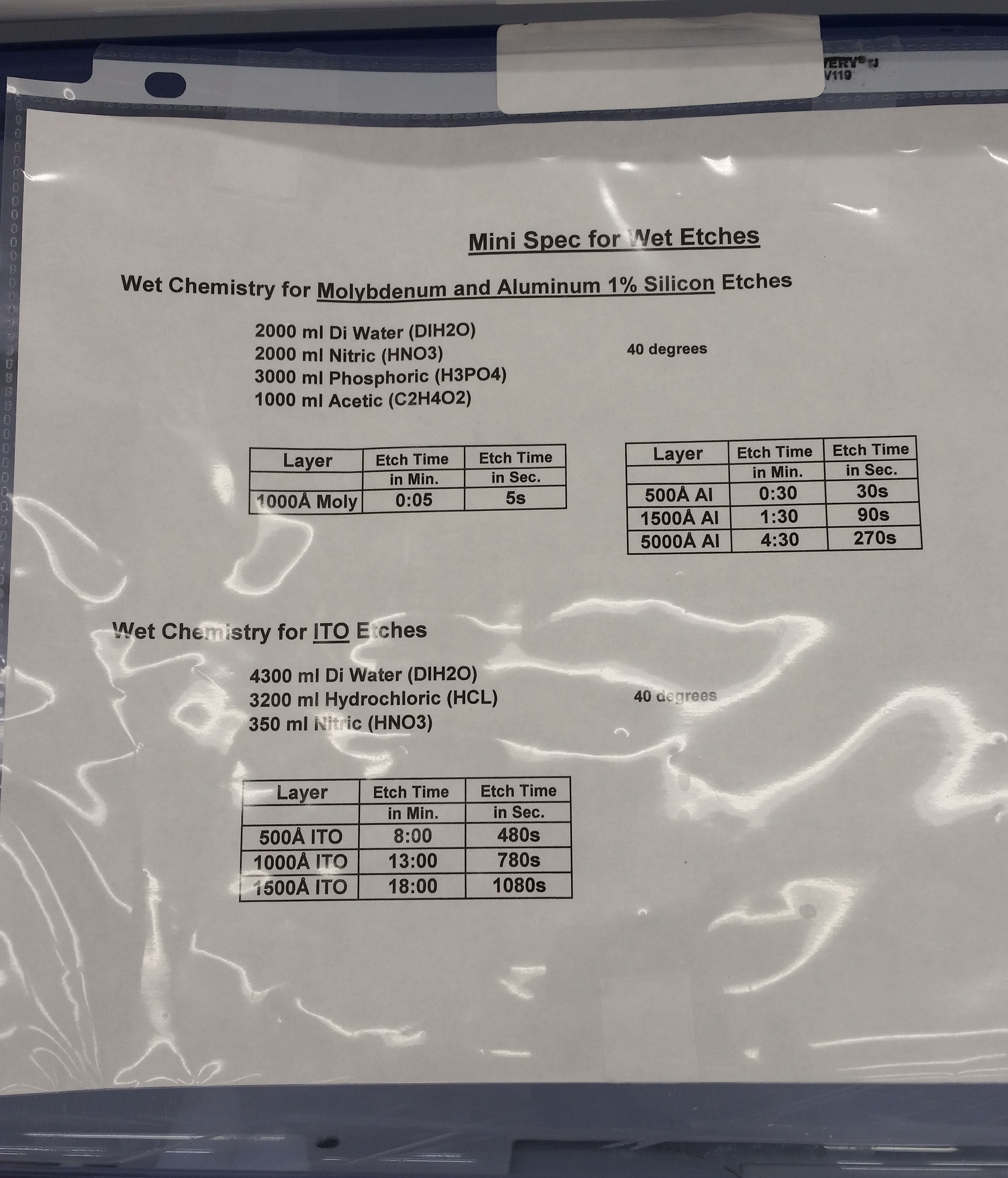

- Deionized water (diH2O) + nitric acid (HNO3) + phosphoric acid (H3PO4) + acetic acid (C2H4O2) - [Moly and aluminum (Al) etching).

- diH20 + HNO3 + hydrochloric acid (HCl) - (ITO Etching).

- PCT Megasonic clean (can be used with Detergent8 soap or without).

- Each chemical tank has a QDR rinse tank associated with it.

- Spin Rinse Dryer to dry the wafers after rinse.

Solvent Hood

- SRS Solvent Strip chemistry.

Equipment and hoods

- One acid hood.

- One solvent hood.

- Other chemistries can be used. Please check with FEDC staff.

Techniques

- Wafer cleaning

ASU Unit

Knowledge Enterprise

Rates

| Service | ASU rate | Nonprofit/other academic rate | Notes |

|---|---|---|---|

| Equipment use | $54/hour | $70/hour |

Photos