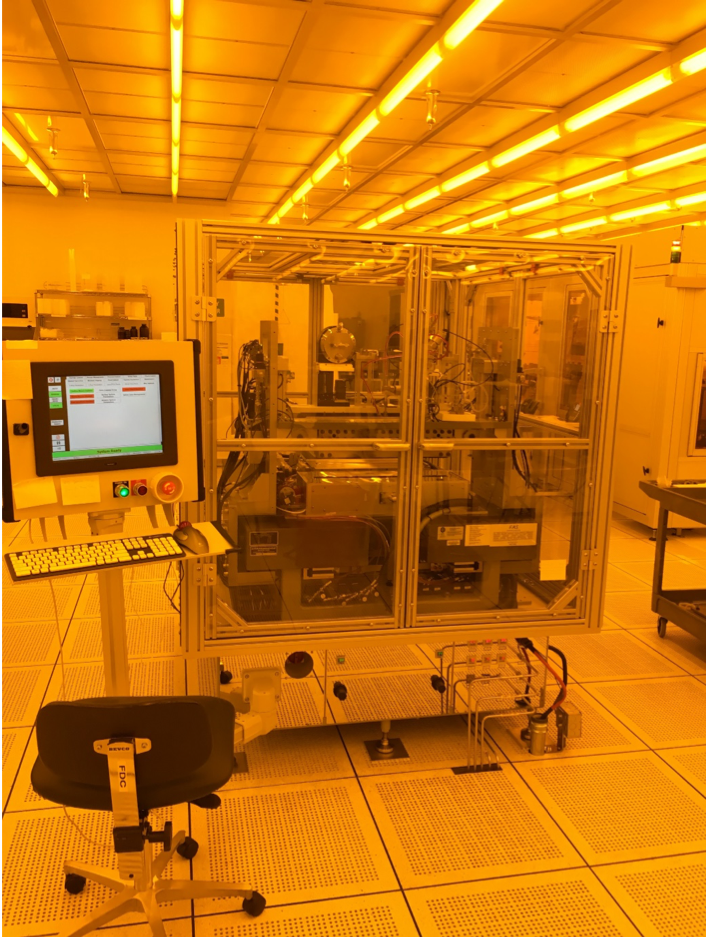

This tool is a photoresist or polyimide coater that uses an extrusion or slot die head to scan across the substrate. Two different slot die heads are used, one for positive photoresist and another slot die head for polyimide coating. The chemical is extruded through the slot die head by using an extremely accurate pump and out through a fine gap lip that then scans across the substrate (glass panel).

The height above the substrate is repeatability-determined by Keyence lasers that constantly measure the height above the substrate while scanning. Once the lasers are calibrated to the surface of the substrate, the slot die head will maintain a specified gap while scanning to ensure a uniform and repeatable thickness coated film.

No bake ovens are supplied with this tool, softbake oven bakes are done using a separate standalone hot plate oven or EVG Softbake ovens.

Substrate film thickness for photoresist is usually measured after softbake using the Woollam Ellipsometer M2000, while the film thickness for polyimide is measured after softbake and hardbake cure on the FP-10 Stylus Profilometer.

Specifications:

Positive Resist .5 um to <10 um (Low Viscosity Die)

Polyimide coating thickness: 5 um to <20 um (High Viscosity Die)

Coating Uniformity within each panel: +/- 5% factory spec, typically +/- 3%

Substrates: Gen II glass .7 mill thickness, 370 mm by 470 mm

Chemical used: AZ1505 positive photoresist, U-Varnish 2000 polyimide, Propylene Glycol Methyl Ether Acetate (PGMEA)

- photoresist coating

- polyimide coating

- FilenTac Slot Die Coater specs.docx34.82 KB

| Service | ASU rate | Nonprofit/other academic rate | Notes |

|---|---|---|---|

| Equipment use | $73/hour | $96/hour |