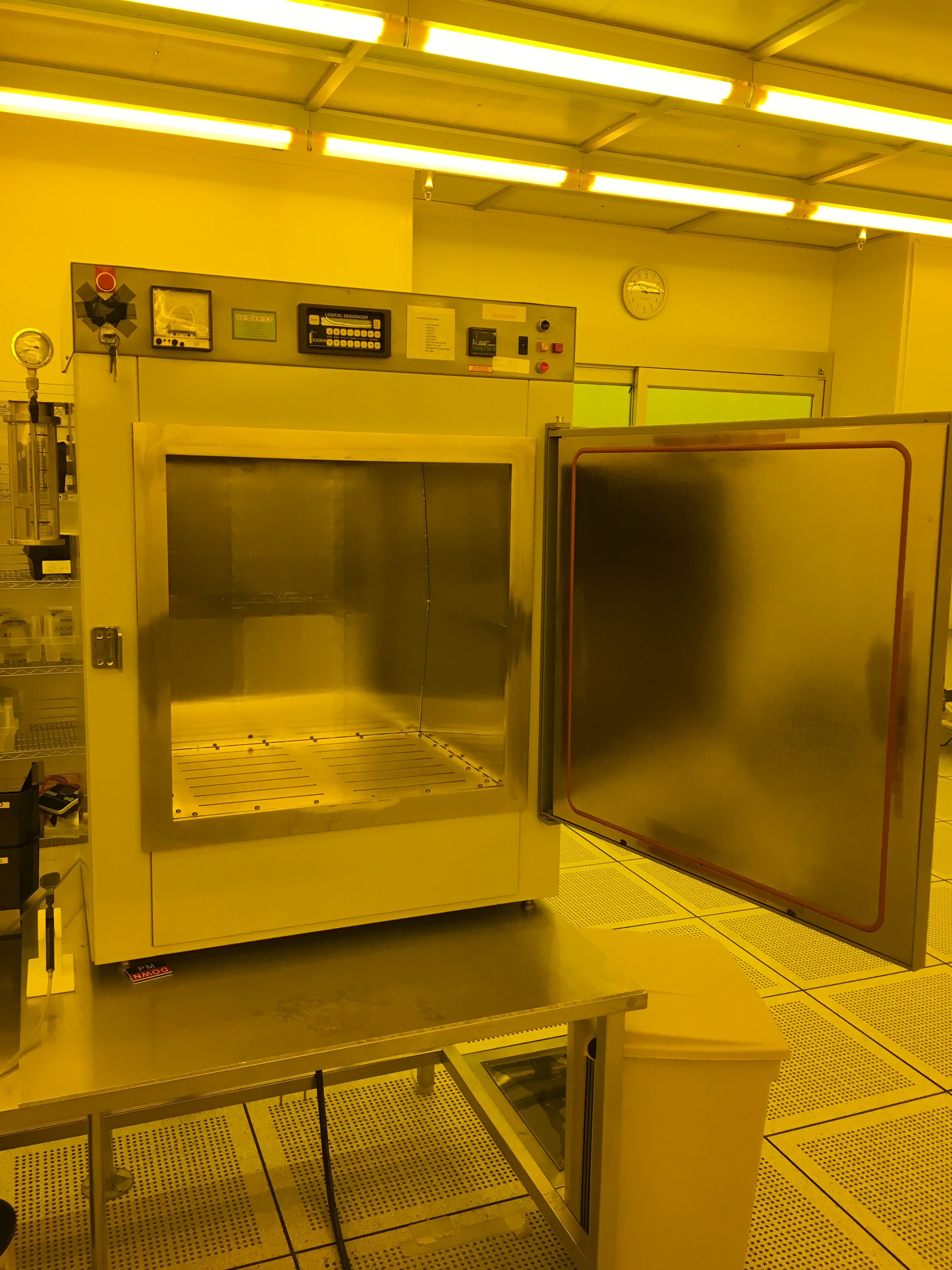

Description

This oven is used to apply HMDS vapors on substrates in a vacuum with heat in order to promote photoresist adhesion.

Specifications:

Chamber size: 26” W x 26” D x 31” H

Substrate size: 2” to 6 “wafers up to Gen II size panels 370mm x 460mm

Oven Temperature: Up to 200 C

Vacuum: Down to 400 mTorr

Vacuum bake HMDS vapor priming is a very effective way to achieve photoresist adhesion by first dehydration of the substrate with heat under vacuum and then applying an adhesion promoter such as HMDS, hexamethyldisilizane. Using this technique creates several advantages:

- 1. Vapor-priming allows the application of HMDS in a monolayer. (The trimethylsialne (C3H9Si) molecule is 5 angstroms tall.)

- 2. It cuts down the chance of contamination by exposing the panels to HMDS vapor rather than liquid.

- 3. This technique requires a small amount of liquid to produce a large amount of vapor.

Techniques

- Photolithography

- Vacuum bake HMDS vapor priming

Documents and manuals

- File

ASU Unit

Knowledge Enterprise

Rates

| Service | ASU rate | Nonprofit/other academic rate | Notes |

|---|---|---|---|

| Equipment use | $59/hour | $77/hour |

Photos