Description

Wet chemical processes

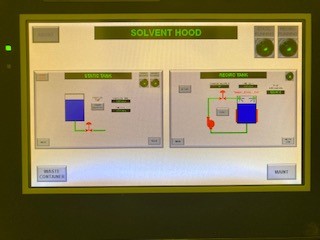

Solvent cleans are used to remove unwanted photo resist. This bench has 2 separate solvent tanks, and a Laurell spin coater. An acid hood is positioned next to tool to allow for DIW rinse the wafers before drying in the spin rinse dryer (SRD). Only one user is allowed in the solvent hood at a time.

Wet Solvent chemical etching is available with the following chemicals:

- Tank 1 – Recirculated solvent tank with ultrasonic capability.

- Tank 2 – A static solvent tank.

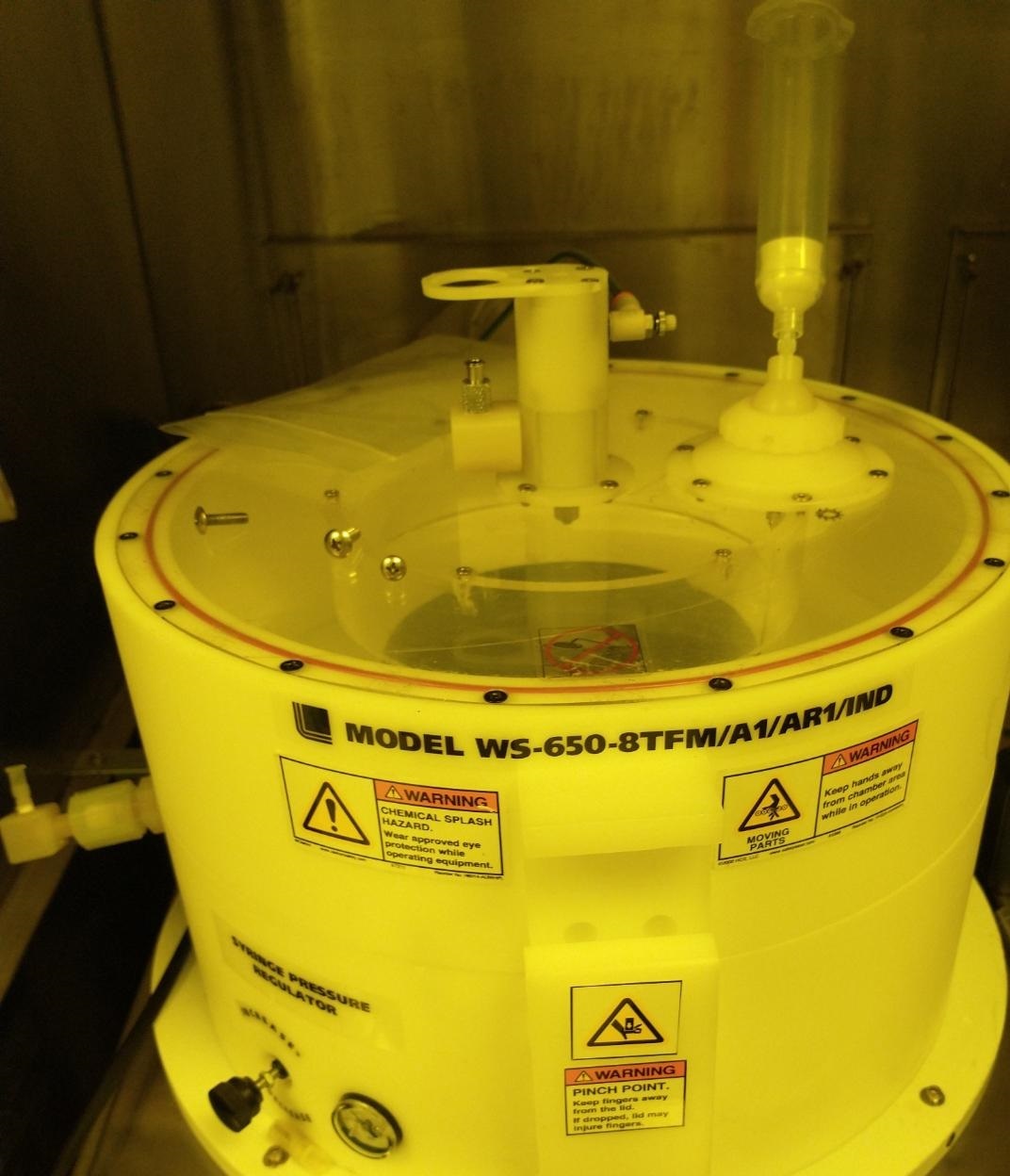

- Laurell spin coater with programable dispense, manual edge bead removal (EBR) and manual back side rinse.

Equipment and hoods

- One solvent hood.

- One acid hood for final rinse.

- One Spin Rinse Dryer.

- Other chemistries can be used. Please check with FEDC staff..

- Solvent drain collection. Please alert AEP Core staff if the collection tank is full.

Techniques

- solvent cleaning

- Spin coating

- EBR

Documents and manuals

- File

- FileLaurell-LITE_650.pdf2.85 MB

ASU Unit

Knowledge Enterprise

Rates

| Service | ASU rate | Nonprofit/other academic rate | Notes |

|---|---|---|---|

| Equipment Use | $54/hour | $70/hour |

Photos